Heavy Metals Policy

This statement describes the processes and controls our factory uses to keep heavy metals out of finished products.

Overview

Manufacturing to exacting standards of purity means:

- Sourcing only high-quality raw materials

- Keeping the factory and manufacturing lines clean to prevent contamination

- Continual oversight at the factory to ensure protocols are followed

- Programmatic testing to ensure no defects or contamination

Raw Materials

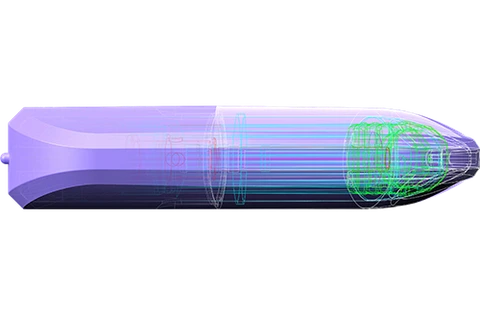

Our products are made from a variety of materials. To achieve the desired quality and performance, we must source our materials from specialty suppliers who can meet our high standards. Our glass is borosilicate, zero absorption, and legendary for its ability to withstand rapid heating and cooling.

Cross Contamination

To prevent cross-contamination our factory takes precautions at every step of the manufacturing process:

- All tooling (i.e., fixtures, jigs, gauges, molds, dies, cutting equipment and patterns) is used solely to manufacture for AVD to avoid cross-contamination with other products manufactured at lower standards.

- Work-sites are regularly cleaned to make sure materials remain contaminant free.

- Each production batch is tested for potential cross-contamination.

- Before being added to the assembly line, all parts are tested by quality control teams for material defects and contamination.

- Our production environments are clean, dust-free and set up for sterile production.

Oversight

We work closely with the actual people and machines that make our products. From testing to oversight we make sure that the right people are in place to ensure the quality of the finished product. This means checking protocols are followed, facilities stay clean, and products are batch tested before they go to our customers.

Final and Batch Testing

Our raw materials are batch tested pre-production to ensure the final product is heavy-metals compliant. A “Finished Testing Process” ensures cartridges are packaged and shipped free of defects and contamination. We also conduct shelf-life heavy-metals testing to ensure that our devices are heavy-metals compliant.

Third-Party Contamination Risk

We strongly recommend you carry out your own testing to ensure your entire supply chain is free of lead and other contaminants. Before mass production, conduct your own preliminary tests. We suggest filing a batch sample of your oil-filled cartridges and submitting samples to a licensed testing facility.